How to Reduce Total-Cost-per-Order by Balancing, Not Overriding Smart Systems

How a fast-growing omnichannel retailer increased the bottom line by 5% by balancing smart systems to work on a common goal, i.e., reduce total-cost-per-order.

Meet Rick, the VP of Fulfillment Operations

Rick joined a fast-growing omnichannel retailer eight months ago with a clear mandate: reduce Total Cost per Order (TCPO) across their four national fulfillment centers.

He wasn’t new to this world. Rick had led a major warehouse transformation at his previous company that shaved 18% off per-order costs. But at his new job, things felt… off. Despite advanced systems and best-in-class WMS modules for slotting, replenishment, picking, and labor planning, the cost per order kept creeping up. Not by much. But just enough to signal something systemic.

The Pieces Fit… But the Puzzle Seemed Impossible

He started digging in. Individually, the systems were “smart”:

- Slotting minimized picker travel.

- Replenishment kept fast movers up front.

- Labor planning matched the forecasted workload.

- Picking sequences reduces zone congestion.

But together? They were fighting each other.

For instance, slotting had moved high-demand items closer to pack-out, great for pickers, except it caused more frequent replenishments and drove up labor in the reserve area. Meanwhile, labor schedules optimized for picking speed weren’t synced with replenishment peaks, leading to missed SLAs and expedited shipments.

What ProfitOps Did Differently

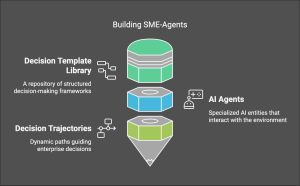

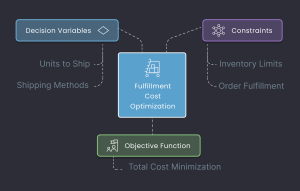

That’s when Rick turned to ProfitOps, a Decision Intelligence platform, built to coordinate different modules around a shared goal: reducing TCPO.

ProfitOps deploys multiple agents working in orchestration toward shared business goals. In this case, two key agents take center stage: the Business Value Indexer (BVI), which tracks north start metrics in real time, and the Deep Cause Analyzer (DCA), which uncovers the root causes behind performance shifts.

The BVI agent immediately began ingesting data from across the tech stack: WMS, LMS, OMS, and even IoT congestion sensors. It tracked KPIs like: Replenishment labor per SKU moved, Picker idle time due to congestion, Travel time overlaps across zones.

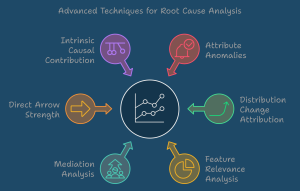

The DCA Agent mapped how these factors influenced each other, sometimes helping, but often clashing and canceling out gains or making problems worse. Understanding these cause-and-effect chains is critical.

What ProfitOps Uncovered ? What is driving TCPO?

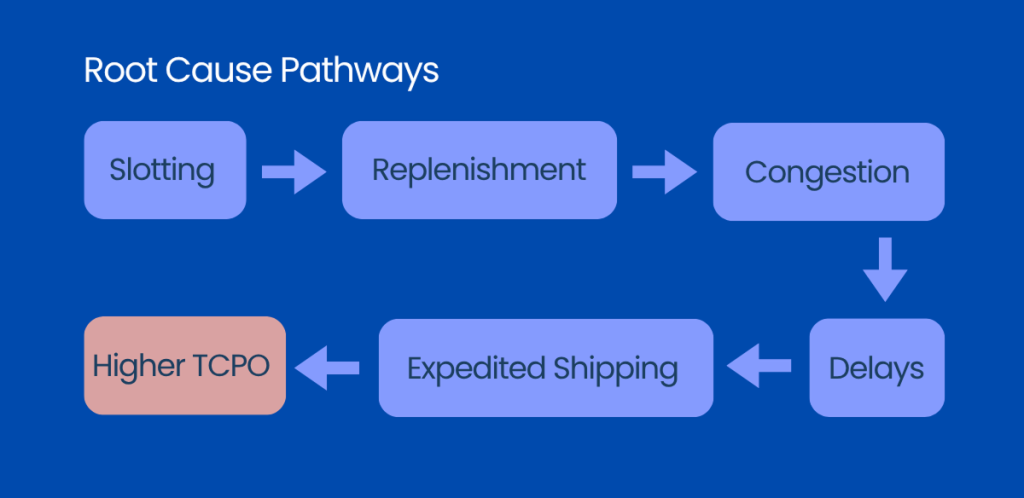

Within weeks, BVI & DCA exposed one such chain reaction:

- Slotting changes were increasing replenishment labor by 24% in one zone.

- That zone’s congestion then led to slower pick rates.

- Slower picks delayed packing and caused missed truck cutoffs.

- Missed cutoffs triggered expedited shipping, the silent killer of TCPO.

With these insights, Rick used the ProfitOps Simulation Room to test a new slotting–replenishment–labor configuration. The simulation predicted a 14% drop in TCPO (from $6.00 to $5.16) if the three systems were rebalanced, even if it meant slightly longer travel time per pick.

What ProfitOps Uncovered ? What is driving TCPO?

Rick didn’t need to overhaul the whole operation. He started by aligning just three zones and tweaking slotting rules for 200 high-impact SKUs.

Within a month:

- Replenishment labor hours dropped by 11%

- Picking costs increased slightly due to longer travel, but delays fell 18%

- Expedited shipments dropped by 40% thanks to better flow and timing

- Total Cost Per Order dropped by $0.84 per order or a 14% reduction

That translated to $1.2M in annualized savings and gave Rick the momentum he needed.

Conclusion

Now, with BVI continuously monitoring trade-offs and recommending system-wide improvements, Rick doesn’t have to babysit every module.

“He now has an integrated real-time adaptive decision layer.”

And he’s already building the case for phase two: value-led orchestration of packing workflows, dock scheduling, and shipping priorities using BVI as the backbone.

By the end of the year, Rick is aiming to take another 5–7% off TCPO not by running faster in silos, but by running smarter as a system.

Ready to transform the way you solve business challenges?

Discover how ProfitOps pinpoints root causes, optimizes operations, and prevents disruptions before they escalate. Our AI-driven Deep Cause Model turns complex data into clear, actionable insights, empowering smarter, faster decision-making.

Shravan Talupula

Founder, ProfitOps